E kiola i nā mea hao pae hao, e hoʻokomo i nā ʻāpana o ka ʻōpala i ka umu ikehu

1. Ke kiola ʻana i ke kaʻina hana: Shell casting mold Precision casting

2. Papa kila: GX130CrSi29 (1.4777) (Hiki ke lilo i kāu koi)

3. Ka ahonui aniani o ke kime: DIN EN ISO 8062-3 kaha DCTG8

4. Geometrical Tolerance o ke kime: DIN EN ISO 8062 - papa GCTG 5

5. Palapala noi: Hoʻopau i nā mea kanu incineration ikehu.

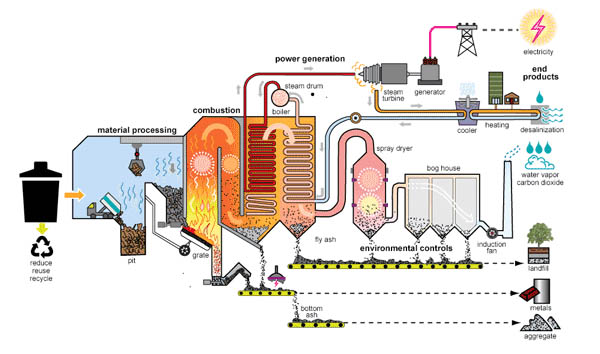

ʻO ka hoʻolei ʻōpala i kēia manawa kahi pilikia nui loa o ka honua. ʻO ka'ōpala i ka ikehu ka lapaʻau kūpono loa i kēia manawa. I nā makahiki i hala iho nei, ua hoʻomaka nā ʻāina he nui me ka ikaika o ka hoʻokele e hoʻolohe i kēia kuhi. Nui ka kālā i hoʻopukapuka ʻia i ke kūkulu ʻana i nā mea kanu mana incineration ʻōpala. ʻAʻole kēia i lawe i ka hoʻomaikaʻi nui i kā mākou kaiapuni. I ka manawa like, ua lawe mai ia i nā pono waiwai nui iā mākou.

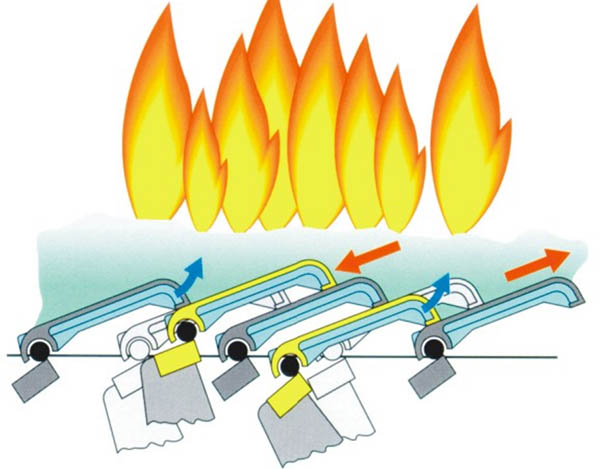

E like me ka mea i hōʻike ʻia i ke kiʻi, hana nui nā pae pae pae i nā mea neoneo. I ke kiʻekiʻe o ka mahana a me ke ʻano paʻakikī loa, e hoʻopili nui ka pae pae haʻahaʻa i ka pono o ka hoʻoneoneo ʻana o ka ʻōpala, a he pōkole loa kona ola lawelawe. Pono ʻoe e pani pinepine.

Eia nō naʻe, me 10 mau makahiki e hoʻolei ana i ka ʻike, hiki iā mākou ke hoʻonā i nā pilikia iā ʻoe.

Hoʻohana maʻamau mākou i ka papa kila. (Hiki iā ia ke like me kāu koi.)

ʻO ka hoʻohui kemika% o ke kila GX130CrSi29 (1.4777): EN 10295-2002

|

C |

ʻO Si |

Mn |

Ni |

P |

S |

Cr |

Mo |

|

1.2 - 1.4 |

1 - 2.5 |

0.5 - 1 |

max 1 |

max 0.035 |

max 0.03 |

27 - 30 |

max 0.5 |

ʻO ka hoʻohui kemika% o ke kila GX40CrNiSi27-4 (1.4823): EN 10295-2002

|

C |

ʻO Si |

Mn |

Ni |

P |

S |

Cr |

Mo |

|

0.3 - 0.5 |

1 - 2.5 |

max 1.5 |

3 - 6 |

max 0.04 |

max 0.03 |

25 - 28 |

max 0.5 |

ʻO ka hoʻohui kemika% o ke kila GX40CrNiSi25-20 (1.4848): EN 10295-2002

|

C |

ʻO Si |

Mn |

Ni |

P |

S |

Cr |

Mo |

|

0.3 - 0.5 |

1 - 2.5 |

max 2 |

19 - 22 |

max 0.04 |

max 0.03 |

24 - 27 |

max 0.5 |

ʻO ka hoʻohui kemika% o ke kila GX40CrNiSi25-12 (1.4837): EN 10295-2002

|

C |

ʻO Si |

Mn |

Ni |

P |

S |

Cr |

Mo |

|

0.3 - 0.5 |

1 - 2.5 |

max 2 |

11 - 14 |

max 0.04 |

max 0.03 |

24 - 27 |

max 0.5 |

| Nā pono hana mīkini (ASTM A297 Papa HH) 1.4837 | UTS: Min 75 Ksi / 515 Mpa |

| YS: Min 35 Ksi / 240 Mpa | |

| Elongation: ma 2 i: Min 10% | |

| Paakiki: Min 200 BHN (3 mau wahi ma ka speciment) " | |

| ʻO Mikrostruktur / Metallography | ʻO ka Promininantly Austenitic hale i loko o nā carbides i hoʻopuehu ʻia |

| Hoʻokolohua / X-kukuna a UT paha | RT no ASTM E446 Papa II |

| UT no ASTM A609 Papa II | |

| NDT / LPI a i ʻole MPI | MPI e like me ASTM E709 / E125 LEVEL II |

| LPI e like me ASTM E165 Papa II " | |

| Nānā Hopena hope loa | ASTM A802 Papa II |

| Pūʻolo | Hihia hao a hihia hihia lāʻau paha. |

ʻO kā mākou mākeke nui

ʻO nā ʻoihana OEM a me nā ʻenehana

Wao i nā mea kanu ikehu

Nā hui hana

Nā kikowaena biomass

Nā mea kanu uila lanahu

Nā ʻoihana lawelawe no nā hana mālama

Nā ʻano like ʻole o nā pae hao OEM

Nā pae pae pae maikaʻi

ʻO ke kaʻina oʻo a me ke kaohi ʻoi loa ka maikaʻi No ke aha ʻoe e koho ai iā mākou

No nā nīnau hou a i ʻole nā nīnau loea, e ʻoluʻolu e kāhea iā XTJ Service Team. E hāʻawi mākou i ka hopena ʻenehana kūpono kūpono a me ka ʻōlelo maikaʻi loa e like me kāu huahana.